Water Electret Nonwoven Pp Meltblown

When the static electret time is prolonged and the static electrical energy is soaked, the water electret meltblown fabric functions at its best.

Product Properties

● Self-bonding

● Large area / weight ratio

● Adjustable structure of pores and capillaries

● Hydrophobic / Oleophilic

● High filtration efficiency

● Electrostatically charged

● Optional additives

Manufacturing Processes

Electrostatic Charge Retention At a certain angle, pressure, and flow rate, the meltblown is sprayed through a cold-water-cold water electret device. Static charge is created by friction between water and melt-blown fabric and is then transmitted to tourmaline or zircon, where it is utilised by the conductive substance in the electret master particle to accomplish electrostatic retention. using electricity to lock and dry

Hot air is used in the drying process to improve surface air movement and boost surface temperature. The method being used is essentially how a static elimination device operates. The electret mastermind will lose all remaining electricity. In the second procedure, some of the virtual electricity present on the melting cloth's surface is removed. The permanent electret on polypropylene can therefore be ensured using the aforementioned two procedures.

Advantages Compared with Normal Meltblown

• Better protective efficacy and better adsorption of viruses, bacteria, and particulate matter in the air compared to standard melt-blown non-woven.

• Effectively stops the transmission of viruses, bacteria, and other airborne contaminants.

Reduced resistance, increased efficiency

Reduced volume of polypropylene stacking

Specification

Technical Performance | |||

Raw materials | 100% polypropylene | Grammage | 20g~35g/㎡ |

Fiber diameter | 1-5 microns | Porosity | ≥75% |

Nonwoven technics | Melt blowing | Width | 175mm/195mm/customized |

Item | Basic Weight | Efficiency | Pressure Drop | Test Methods |

JM020F9W | 20g±3g | Min. 75% | Max. 5Pa | Test method: TSI 8130 |

JM020E10W | 20g±3g | Min. 85% | Max. 8Pa | |

JM020E11W | 20g±3g | Min. 95% | Max. 11Pa | |

JM025E12W | 25g±3g | Min. 99.5% | Max. 20Pa | |

JM025H13W | 30g±3g | Min. 99.95% | Max.30Pa | |

JM035H14W | 35g±3g | Min. 99.995% | Max. 40Pa | |

Remark: Customized Specs acceptable. | ||||

Application

● Face masks/ respirators material

There are two series of items for mask filter material, including medical and labor insurance.

Medical mask materials can fulfill the European standard EN14683, which requires that they have virus, particle, and bacterial filtration efficiencies all be over 99%.

The labor protection mask's filter material complies with Chinese standard GB 2626 dust mask, Japanese MOL standard, American NIOSH42 CFR-84, and European standard EN149.

Additionally, it may be produced to meet many standards for protective dust mask and gear, including European standard FFP1, FFP2, FFP3, American standard N95, N99, N100, R95, R99, Japanese standard DS1, Korean standard KF94, National standard KN90, KN95, KN100, KP90, KP95, KP100, and others.

● Air filter material:

It can be used to create mini-pleated filters, panel filters, pocket filters, and other medium-high efficiency filtration systems that are widely used in cleaning room purification systems, central air conditioning systems, automobile air conditioning systems, and other medium-high efficiency filtration systems.

● Hygiene material & wipes

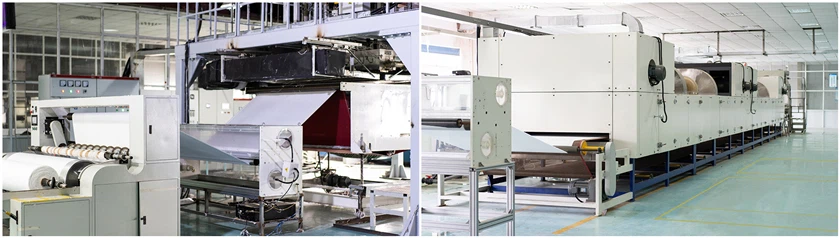

Pictures

Packing & Storage

Packaging: Our melt-blown non-woven fabric will be shipped in rolls, wrapped in stretch films for protection, and labeled with all pertinent data, such as weight, width, and item number.

Storage: The item should be kept in a dry, ventilated area that is difficult to isolate.

You Might Also Like

Send Inquiry